How the Air Force got smarter about its aviation fuel use in 2018

Did you know the Air Force is the largest consumer of fuel in the Department of Defense? This may not surprise you, if say, you’ve ever watched a sortie of F-35s complete an aerial refueling, or witnessed a C-5 lift (seemingly) effortlessly into the sky. In fact, the Air Force consumes approximately 2 billion gallons of aviation fuel annually – which is about 81 percent of the total Air Force energy budget (with about 17 percent used for facilities and 2 percent for ground vehicles).

Operational energy, or aviation fuel, is critical to mission success – but getting fuel to the warfighter involves complex logistical and technical challenges, intricate planning, and more importantly, poses safety risks to the troops transporting it. As the battlefield becomes increasingly multifaceted, energy resilience is a top concern for the Air Force, and optimized operations are an essential component to maintaining it.

Air Force Operational Energy (SAF/IEN), headquartered at the Pentagon, is dedicated to championing energy-informed solutions that increase combat capability across the Air Force. The office is made up of subject matter experts in aviation, aeronautics, fuel logistics, data research, acquisitions, maintenance, and strategic engagement who look for ways to increase efficiency through new technologies, data solutions, and innovative process improvements.

In the past year, the office saw success in a number of areas. Here are just a few ways they’ve helped the Air Force get smarter about operational energy in 2018:

Established a fuel data collection strategy across the Force to pinpoint inefficiencies and analyze consumption trends

Fuel data is crucial to identifying and understanding operational inefficiencies in the Force. By collecting and analyzing fuel data from across all aircraft, the Air Force can measure its effectiveness, enable data-driven decisions, and better target opportunities to improve operations that deliver competitive advantages against adversaries.

Historically however, the Air Force has not captured and retained sufficient aviation fuel data to accurately evaluate its operations. At the end of 2017, only about 30 percent of Air Force fuel use was captured in a sortie-level database.

In 2018, Air Force Operational Energy drafted the Operational Energy Data Collection Strategy to lay the foundation for collecting and storing aviation fuel use and associated mission execution data. The purpose of the Strategy is to set the Air Force on a course to collect aviation fuel data that is comprehensive, automated, high-resolution, and accurate. Implementing the Strategy will inform operations, support a resilient and innovative Air Force, and integrate aviation fuel data collection into a wider data and IT strategy across the Air Force and Department of Defense.

Incorporated operational energy into wargaming

Operational energy challenges and solutions are now an active part of Air Force wargaming due to an Air Force Operational Energy initiative. In 2017, the office became involved in the planning and development of the Air Force’s Title 10 Wargame series, which led to their active role in Global Engagement 2018, Global Mobility/Agile Combat Support 2018, Long Duration Logistics Wargame 2018, and Futures Game 2019.

The office’s participation – along with support from aligned organizations such as Naval Postgraduate School, Headquarters Air Force Logistics (A4) and Plans (A5), Air Force Petroleum Office (AFPET), Defense Logistics Agency - Energy, Office of the Secretary of Defense for Operational Energy, and industry partners – enabled unprecedented incorporation of the fuel supply chain (from refinery to aerial tanker) into the 2018 wargaming campaign and highlighted the key role operational energy plays for combat operations at bases and beyond.

Ultimately, their goal is to facilitate better understanding of logistical challenges and to drive energy-informed leadership decisions in wargaming - and ultimately in basing strategy and investment priorities.

Identified efficiency best practices for the C-17A fleet

Air Force Operational Energy, in coordination with Air Mobility Command (AMC), tasked the Energy Analysis Task Force (EATF) to complete a Line Operations Efficiency Analysis (LOEA) on the C-17A fleet, one of the DoD’s largest consumers of aviation fuel.

To accomplish the LOEA, the EATF interviewed Airmen at Joint Base (JB) Charleston, JB Lewis-McChord, JB McGuire-Dix-Lakehurst, and Wright-Patterson Air Force Base (AFB) from April to September 2018. After reviewing flight manuals and operational guidance materials, surveying crew members to understand C-17 energy efficiency techniques and mindsets, and soliciting ideas from crew members and leaders, the EATF published an official report, distributed to Air Force senior leaders at the end of 2018, outlining the following:

-

Efficiency best practices for C-17A operations

-

Operational fuel efficiency assessments for the C-17A and recommendations on efficiency opportunities across the fleet

-

A reference point for aviation energy awareness and culture in the C-17A community

The EATF is scheduled to complete the next Line Operations Efficiency Analysis on the KC-135 fleet in 2019.

Inserted operational energy lesson plans into Air Force Institute of Technology (AFIT) programs

In 2018, Air Force Operational Energy funded the development of two graduate courses at the Air Force Institute of Technology (AFIT), Department of Systems Engineering and Management. The two courses, Aviation Energy Systems Engineering and Contingency Base Energy Systems Engineering, will be offered for the first time in the spring of 2019. The collaborative effort to develop these courses has ensured that operational energy is at the center of lectures and research efforts, and is a significant step toward the office’s goal of educating the Force and building an operational energy-aware culture.

Introduced light-weight parts into operations to reduce aircraft weight

Aircraft weight is a key aspect of fuel burn, so the heavier the aircraft, the more fuel it takes to fly it. Air Force Operational Energy is exploring a number of avenues to reduce weight, and therefore fuel burn, on aircraft.

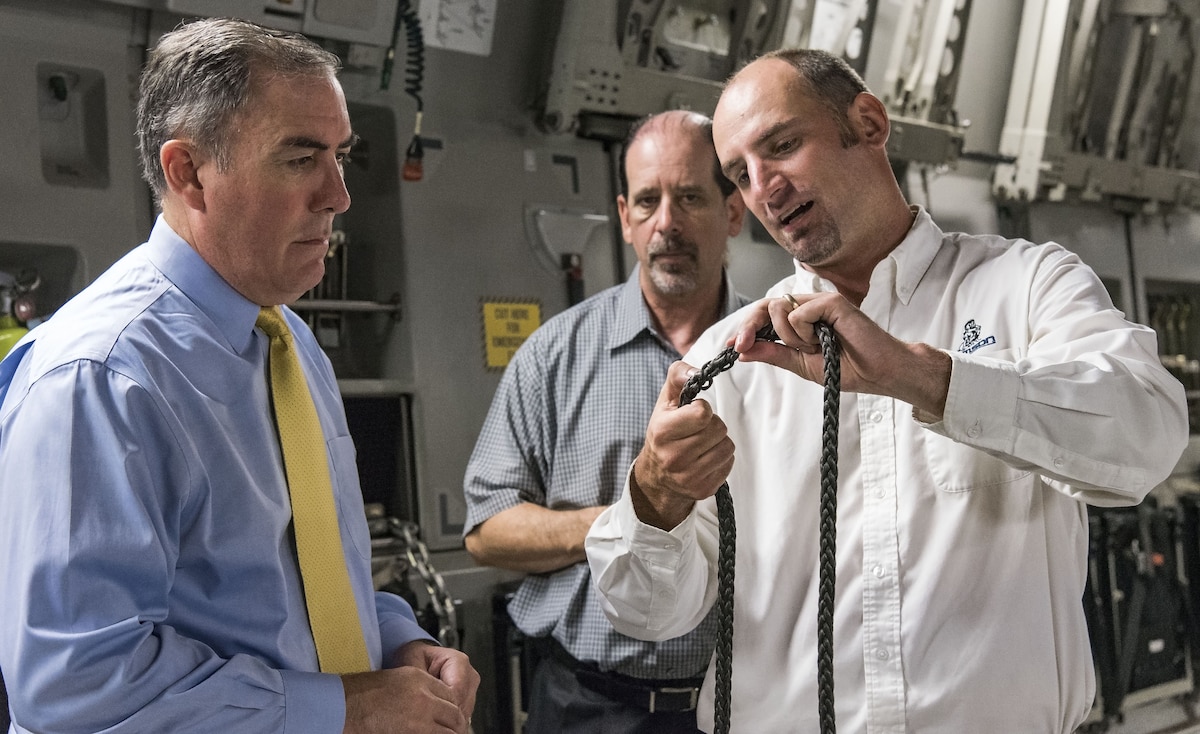

In 2018, the office initiated a project to replace heavy metal chains with lightweight synthetic tiedowns and winch cables on the C-17, reducing aircraft weight by approximately 1,000 pounds per aircraft. The synthetic cables and tiedowns are just as strong as the metal chains they are replacing, far easier to handle (reducing load time and workload), while also being safer for Airmen as they are less likely to recoil dangerously. The cable is now cataloged as a part number and has transitioned to fleet use, while the tiedowns are in the final phases of development before fielding.

Another Air Force Operational Energy project has worked to replace legacy aluminum honeycomb air inlets with lightweight composite RAM Air Inlet system for the C-5M Super Galaxy, which are 19 percent lighter and cost almost $100,000 less per part to manufacture. The composite parts have met all tests for strength and durability, and have a greater corrosion resistance, increasing part life and aircraft availability while reducing maintenance costs. The new inlets have transitioned to operational use and will replace the aluminum parts on an attrition basis.

Updated max range airspeed policy resulting in optimized operations

Due to an optimization initiative led by Air Force Operational Energy, policy has been put into place that directs planners to plan airspeeds for 5th generation fighter Coronet missions at closer to maximum range airspeed. The faster speed decreases overall fuel consumption by about 6 percent, and reduces flight hours by about 10 percent. After a successful demonstration with F-22s at the end 2017, the office continued working with ACC and AMC in 2018 to formalize the procedures and expanded them to include the F-35.

Read the full story here.

Air Force Operational Energy seeks to connect Airmen with technology, data, and innovative thinking to develop and champion energy-informed solutions across the Air Force. For more information and news visit: www.safie.hq.af.mil/OpEnergy/, www.Twitter.com/AFEnergy, and www.Facebook.com/AirForceEnergy.